MX1919 Dual H-Bridge Motor Driver

The MX1919 is a low-cost MOSFET-based dual H-bridge DC motor driver which is capable of driving two DC motors in Bi-direction. This motor driver IC can deliver up to a 3.5A peak current and 1.6A continuous current on both channel at a time. While only one channel is active the continuous current can reach up to 2.3A. It has four inputs to control the direction of two motors. It can be operated with a 2-10v power supply. The MX1919 Offers a thermal shutdown feature. This small size is suitable for hobby robotics and toy products. This IC is available in a DIP16 package.

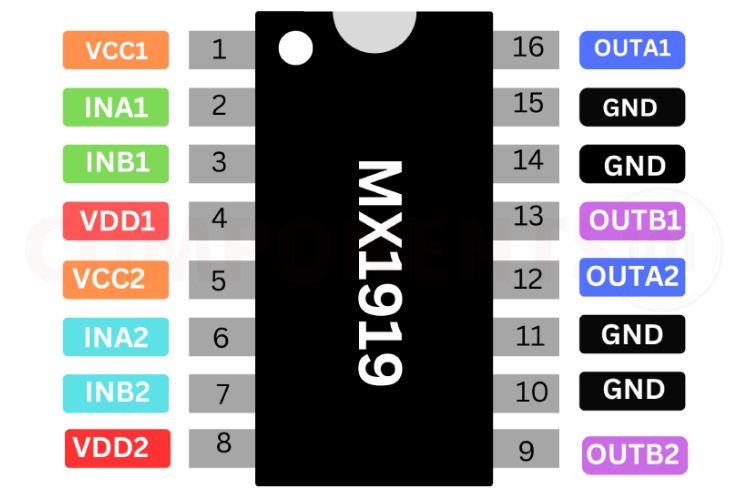

MX1919 Pinout Configuration

Here are the pinout details for MX1919.

| Pin number | Pin name | Pin function description |

| 1 | VCC1 | 1Channel logic control power terminal |

| 2 | INA1 | 1Channel forward logic input |

| 3 | INB1 | 1Channel inversion logic input |

| 4 | VDD1 | 1Channel power supply terminal |

| 5 | VCC2 | 2Channel logic control power terminal |

| 6 | INA2 | 2Channel forward logic input |

| 7 | INB2 | 2Channel logic input |

| 8 | VDD2 | 2Channel power supply terminal |

| 9 | OUTB2 | 2Channel inversion output |

| 10 | GND | ground terminal |

| 11 | GND | ground terminal |

| 12 | OUTA2 | 2Channel forward output |

| 13 | OUTB1 | 1Channel inversion output |

| 14 | GND | ground terminal |

| 15 | GND | ground terminal |

| 16 | OUTA1 | 1Channel forward output |

Features of MX1919

MX1919 dual-channel bi-directional DC motor Driver has the following key features.

- Wide supply voltage(2-10)

- Higher peak current (3.5A)

- low standby current (less than0.1uA);

- Low quiescent operating current;

- Integratedhbridge drive circuit;

- Built-in anti-common state conduction circuit;

- low on-resistance powerMOSFETsTube;

- Built-in thermal protection circuit with hysteresis (TSD);

- Antistatic grade:3KV (HBM).

Manufacturers of MX1919:

The MX1919 is manufactured by CENROKERSING. There are no alternative manufacturers for the same part number as of the date of writing this article.

MX1919 Equivalents

There is no pin-to-pin compatible equivalent for MX1919.

MX1919 Alternatives

If you are looking for an alternative for DRV8837 you can look at the other ICs from these.

L293D, L298, TB6612FNG, DRV8833, MAX1508, TA6586, DRV8837, DRV8871, L9110

Note: Complete technical details can be found in the MX1919 datasheet at this page’s end.

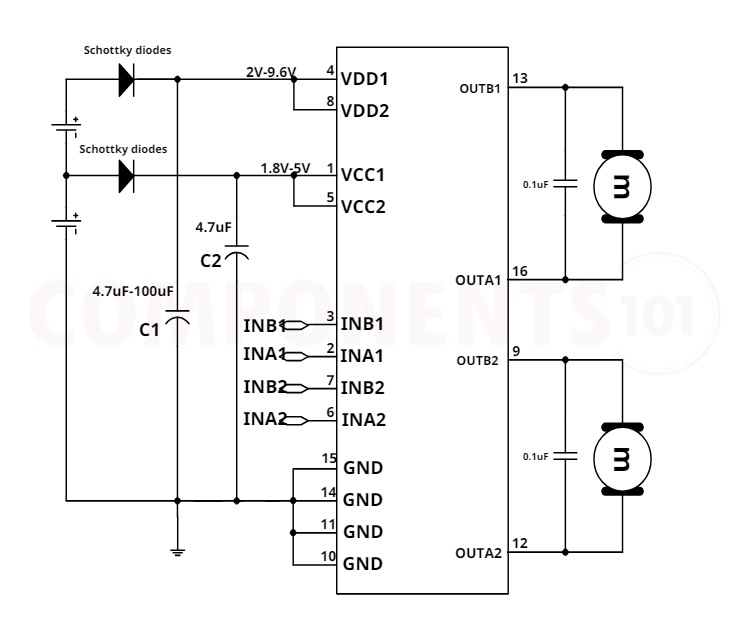

MX1919 Schematics

The following image shows the typical circuit diagram for MX1919.

The above circuit diagram shows how to connect and drive a motor using MX1919. In this circuit, the motors are connected to two output channels. All the grounds are connected to the ground of the circuit commonly. The drive circuit requires an added power supply, VDD1, and VDD2 connected with a decoupling capacitor(C1) to the ground. We have four inputs to control the two motors in two directions, we connect these input pins to any microcontroller or logic circuits to control the IC. You can control the motor according to this truth table Here we added the 0.1uf capacitor parallel to the motor to avoid jerking. The connected schottky diodes help to overcome reverse polarity.

| INAx | INBx | OUTAx | OUTBx | Function |

| L | L | Z | Z | standby |

| h | L | h | L | Forward |

| L | h | L | H | reverse |

| h | h | L | L | brake |

Note: The x represent either Input 1 or Input 2

Having Trouble with MX1919?

MX919 circuit is resetting when powered on?

It might be due to the voltage spike/load drawing more current than the rated range, so check the motor supply voltage and also try to add a capacitor parallel to the motor.

MX191 IC not working what should I check?

1. Check all connections, and make sure everything is connected properly.

2. Check the motor voltage and current. Make sure that the rating is in the range of IC rating.

3. Check if the ground of the motor power supply and the logic circuit are commonly connected.

The IC gets very hot and automatically turns off:

- Overloading: The motor driver IC may be driving a motor that draws more current than the IC can handle. Check the datasheet for the maximum current rating of the motor.

- Voltage Spikes: If there are voltage spikes or transients in the motor circuit, it could cause the IC to overheat. Adding capacitors to suppress these spikes can help protect the IC.

- Poor Heat Dissipation: The IC may not be dissipating heat efficiently. Make sure the IC is operating below 100 degrees Celsius

- The motor is jerking: make sure the voltage and current rating of the motor match with the IC maximum parameters. Add .1uf capacitor parallel to the motor pins to reduce the noise.

How to do MX1919 Arduino Interfacing?

For controlling the MX1919 you will need four GPIO pins. Connect the inputs of MX1919 to these pins, set them as output and by changing the state of these pins you can control the MX1919 and the motor connected to it. You can refer to the truth table given above.

Is a heat sink necessary for the working of MX1919?

No. For most applications, the MX1919 can operate without a heat sink within its specified operating conditions.

Design Choices to be Considered with MX1919

Reverse connection between power supply and ground

Reversely connecting the power supply of the circuit to the ground wire will cause damage to the circuit, and in severe cases, it will cause smoke from the plastic package. It can be considered to connect two power Schottky diodes in series to the positive terminal of the battery at the power supply end of the circuit to prevent circuit damage caused by the reverse connection of the battery. The maximum continuous current capability of the power Schottky diode must be greater than the continuous current of the motor stall, otherwise the Schottky diode will be damaged due to overheating. The reverse breakdown voltage of the power Schottky diode must be greater than the maximum power supply voltage. If the reverse breakdown voltage is too small, the Schottky diode will break down and burn out when the battery is reversed.

Decoupling capacitor to ground

By adding a decoupling capacitor between the ground and VDD1, VDD2 will help to Absorb the energy released by the motor to the power supply, stabilize the power supply voltage, and avoid circuit breakdown due to overvoltage. Also at the moment of starting the motor or switching between fast forward and reverse rotation, the motor needs a momentary high current to start quickly. Due to the response speed of the battery and the long connection leads, it is often impossible to output a large transient current immediately. At this time, it is necessary to rely on the energy storage capacitor near the motor drive circuit to release the transient large current.

PCB Layout Consideration

Grounding: Proper grounding is crucial to minimize noise and interference. Use a solid ground plane.

Current Capacity: The motor driver can handle high currents, so make sure that tracks have enough width.

Decoupling Capacitors: Place decoupling capacitors close to the motor driver's power pins and connect them to the ground plane with short and wide tracks.

Signal Tracks: Keep signal tracks short and direct, especially for control signals to and from the microcontroller or other logic circuits.

Applications of MX1919

- Robotics

- Printers

- Motorised Vehicles

- Toys

- Solar Tracking System

- DIY Projects

MX1919 Footprint Information and Dimensions

Here you can find the mechanical drawings of MX1919 along with its dimensions. The dimensions can be used to create a custom footprint of the chip and can be used for PCB or CAD modelling.