TE Connectivity's UAM Wi-Fi Triple Band Antennas offer a compact alternative for terminal antennas

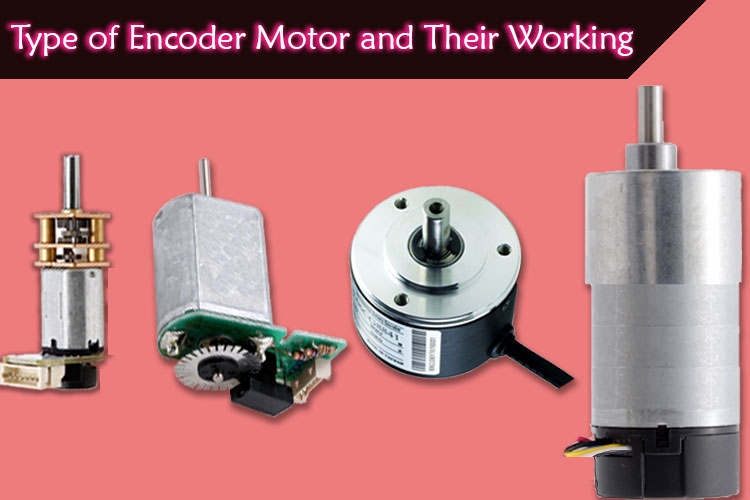

Different Types of Encoder Motors and their Working

When it comes to precision control, a stepper motor is the first thing that pops into our head, but sometimes there are situations where you need precise control, but not that extreme. We can use an automatic door locking system as an example. Or maybe you want to rotate the motor shaft 360 degrees back and forth just like a washing machine. In such a situation, choosing a stepper motor is not only inefficient but also costly. The solution to this type of problem is a simple Encode Motor that is much cheaper than a conventional stepper motor and can also produce a lot more torque than a stepper motor.

So, in this article, we decided to talk all about different types of encoder motors and their working principle. We will also talk about how you can use a simple microcontroller like Arduino to read it.

What is an Encoder Motor?

An encoder motor is a type of motor in which a rotary encoder is mounted to its backside that provides feedback to the system by tracking the speed or the position of the motor shaft.

There are a wide variety of encoder motors available in the market. some of them are optical or magnetic while others are incremental or absolute. The type of encoder can depend upon the shape, size, and application type.

How does an encoder work?

In any rotary encoder there are two outputs, labeled A and B or they can be something similar depending upon the product. But the underlying concept stays pretty similar, for the sake of simplicity, we can imagine a rotary encoder as like two switches inside the encoder, which is made common with VCC or GND (Depends on the manufacturer), now when it rotates the common terminal touches the A terminal or the B terminal, the terminal is so placed that if the encoder is rotating clockwise, contact A will go high, next contact B will go High, this means that depending upon the direction (clockwise or counterclockwise), there will always be a 90-degree phase shift. And we can simply detect this phase shift with the help of a microcontroller to determine the direction of the rotation and once we do that, we can increment or decrement a counter which tells us the RPM or the degree of rotation (in case of a geared encoder motor). The image below will give you a better idea of the process.

If you want to know more about the working of an encoder motor, you can check out the article on Incremental directional encoder on Wikipedia. Else, you can check out our article on Working of Rotary Encoder Module Pinout Circuit

Different Types of Motor with Encoder

Depending upon the application, there are many different types of encoder-based motors to choose from. The most common ones are listed below.

AC Motors with Encoders:

Not only DC motors, but there are also AC motors with encodes that are available in the market. An AC induction can be a common choice for generic applications and control systems as they come with low cost and long life. These types of motors are used in lathe machine where precise speed control is needed

Stepper Motor with Encoders:

When we hear about a stepper motor with an encoder, the first thing we will think is why do we even need a stepper motor with an encoder. Isn’t its precise control actually what the stepper does its best? The answer to this question is ‘yes’ and ‘no’ at the same time. A document released by GALIL on Closed-Loop Stepper Motor says otherwise. They say that the guidance given by an encoder can have a large impact on how precisely can a stepper motor works. The paper talks about a side-by-side comparison of open and closed-loop stepper motor systems, and they found out that an additional encoder can improve the stability of the system to a certain extent. With this technique, they achieve more torque and it also improves the smoothness of the motor significantly.

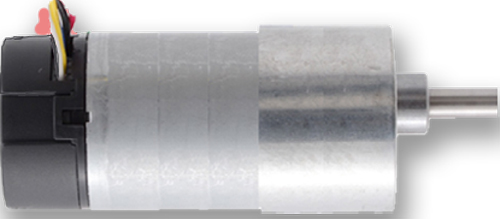

DC Motor Encoders:

A DC motor with an encoder is the most common type that can be found in the market. In most cases, it is a generic DC motor with a magnetic type encoder attached to its backside and on the front side, there may or may not be a gear assembly that reduces the RPM and increases the torque. The encoder provides closed-loop feedback to the system through which the RPM of the motor can be adjusted preciously.

Types of Encoder Technology

Depending on the application, there are many different types of rotary encoders to choose from. A list of which is given below.

Optical encoder:

An optical encoder is one of the most commonly used encoders and it is composed of a light source a revolving disk and a light detector circuit. When it is powered on the light source or the LED is powered on and in the extreme opposite, that light source is the photodetector and in between, the encoder disk is placed. The encoder disk consists of a black disk that has preciously cut holes in between, through the holes the light is received by the photodetector, and it’s interrupted when there is no hole present. This makes the light pulse that is processed by the microcontroller and then it determines the direction in which it’s rotating, a mouse is a great example of this type of encoder.

Linear encoder:

A linear encoder is a type of encoder that is mostly used in industrial automation and control. It is a device that has a linear scale that determines its position. On the scale, there is a sensor, it can read the scale and determine its position. A digital vernier caliper is a great example of a linear encoder. Linear encoders may or may not be absolute or incremental. This type of encoder is used in high-precision instruments like lathes and industrial automation tools.

Absolute encoder:

One of the most interesting encoders that you could learn about is the absolute encoder. Unlike an incremental encoder that provides continuous streams of bits while rotating, an absolute encoder is a type of encoder that outputs unique word bits for each position in space. This provides higher resolution than other incremental encoder types, also it can be adapted to different types of microcontrollers for better performance.

Incremental encoder:

An incremental encoder is another most common type of encoder that is commonly used for different types of applications. It is an encoder that converts angular motion to digital/analog signal depending upon the encoder type. An incremental encoder can be used to determine the position of the shaft of the motor and it’s used mostly in servo motors.

With that being said, now you know quite a bit about encoder types and their working. If you have questions regarding the article you can put them in the comment section below.