TE Connectivity's UAM Wi-Fi Triple Band Antennas offer a compact alternative for terminal antennas

Carbon Film Vs Metal Film Resistors

Invented in the year 1959 by Boykin, Resistors are widely used in almost all electronic circuits today. Resistors can be defined as a device that resists the flow of current flowing through itself, back when it was introduced the size of the resistors was very huge and the tolerance value reached as high as 10%. Furthermore, they were usually made of compressed carbon. Cut to the present time, resistors are often made with metal films and is available in small SMD packages with a tolerance value as low as 2% or even less in case of precision resistors. Some of the leading manufacturers of resistors in India are Carmet, KWK, Epcos India Pvt Ltd. and more. If you didn’t know, India makes up for some 34% of the demand for passive components like resistors by manufacturing them the rest are imported.

If you are interested to know more about Resistors Working and Characteristics then you can try reading this article. In this article, we will discuss the difference between Carbon Film Resistors and Metal Film Resistors.

Brief Intro to Resistors

The word Resistor is born out of the word “resist”, which means to withstand the effect. A resistor resists, directs, or regulates the flow of electrons that pass through it. This is done with the help of the conductive material that it is made out of. The name makes sense now, doesn’t it? Resistors are connected in parallel and series as per the current and voltage requirements.

These little devices regulate, attenuate, or reduce voltage and current, but do not have a source of power on their own. The current flows through them in a regulated manner leading to a loss of energy in the form of heat. Two resistors connect and pass on a current between them only when there is a potential difference. Yes, they follow ohm’s law. We’re sure, you must have heard of this law. Well, it is something to swear by in the world of electronics and electrics.

Moving on, there is an endless list of different types of resistors like composition type, film type, and wire-wound type of resistors depending on their characteristics. To name a few of these characteristics - physical size, reliability, temperature rating, noise, temperature coefficient, and voltage coefficient.

Well, you know the drill. However, we are here to talk about two very important kinds of resistors that are capable of transforming your electronic circuits.

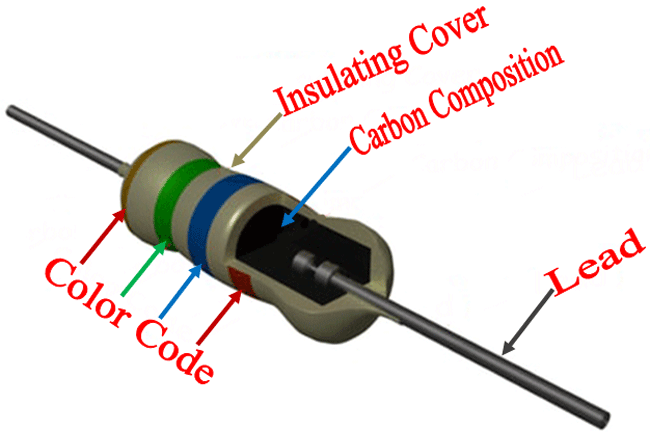

Carbon Film Resistor

Before we begin talking this, let us first contemplate what film resistors are. Well, these are simply those resistors that are formed after depositing oxide film or pure metals on a substrate or some insulating ceramic. The layer is extremely thin and the whole process is known as sputtering.

Carbon Film Resistor is prepared by depositing carbon film on the ceramic substrate which is an insulator. The electric current is blocked to a certain extent by the carbon film. On the contrary, the insulating ceramic doesn’t let heat through it, which in turn makes the carbon film resistor capable of withstanding massive temperature without being damaged. Available between 1ohm to 1 Mega ohm, Carbon film resistors have a decent tolerance value.

Talking about the negative temperature coefficient of resistance - the property of observing a decrease in resistance in reaction to an increase in temperature, these have a high negative temperature coefficient making them susceptible to decreasing resistance as the temperature rises.

Also, these resistors are available at low cost and have a very low tolerance. They operate in a wide range. Applications of Carbon film resistors are widely in X-Rays, power supplies, and RADAR.

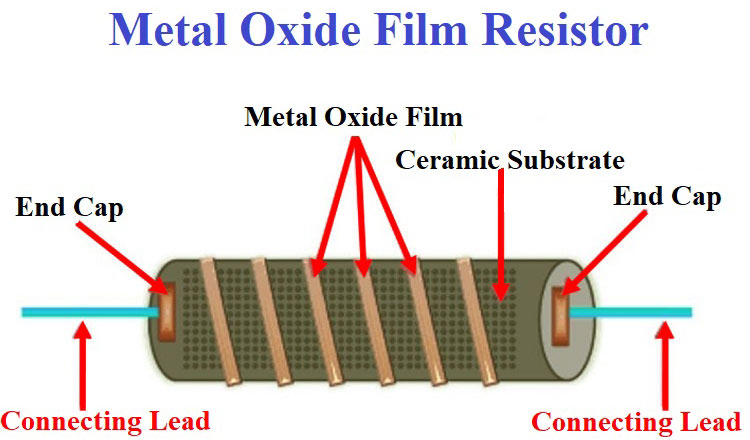

Metal Oxide Film Resistor

In contrast to carbon film resistors, metal oxide film resistors use thin metal oxide films to coat an insulating ceramic rod. The compound made out of oxygen atoms and other atoms works wonders in forming a coating film. However, metal oxide film resistors are made using tin oxide. Also, antimony oxide is added to yield better resistance.

Moving on, these resistors are capable of withstanding high temperatures due to the presence of an insulating ceramic rod that doesn’t let heat pass through itself. At the same time, metal oxide resists the current. The more the antimony, the more is the resistance. But that doesn’t even end here, metal oxide film resistors heavily depend on the thickness of the metal oxide and the width of the helical metal oxide film cut for good resistance. The width of the helical metal oxide film cut and the thickness of the metal oxide are inversely proportional to the resistance.

Wondering what makes them special? As a matter of fact, resistors come at a very low cost and withstand high temperatures while making very less sound. Also, they are small in size along with high reliability and stability. Win-Win!

Carbon Film Resistor Vs Metal Oxide Film Resistor

Well, engineers are always in a dilemma about which one to use. Whether to use the carbon film resistor or the metal oxide film resistor. Alright, let us break it down for you, bit by bit. After all, you want your experiments to go spot on, now don’t you?

According to our comparison between Metal Film and Carbon Film Resistors, we feel Metal-oxide film resistors triumph over carbon film resistors due to certain properties that they possess which are discussed below.

Voltage and Temperature Coefficient

Metal Oxide film resistors have a better voltage coefficient and temperature coefficient than carbon film resistors. The voltage coefficient is the change in resistance with respect to the change in the voltage. In short, it is the ratio of the change in resistance to the change in the voltage. As a matter of fact, metal oxide film resistors work in a wide resistance range and can withstand a higher temperature than the carbon film resistors.

Noise Design Metal Oxide film resistors have low noise design as compared to the carbon film resistors. They keep current to the minimum. Thus, ensuring less noise.

If you didn’t know, metal oxide film resistors make up for better resistors for radio frequency or high-frequency application in comparison to the carbon film resistors.

Tolerance The minimum tolerance level of carbon film resistors of 2% doesn’t stand a chance against that of metal oxide film resistors which can go as low as 0.1%.

Size

Finally, the size of the metal oxide film resistors is smaller as compared to the carbon film resistors making them a better option to go for.

Now that we have done our bit in making you see the nuances of both the kinds of resistors, you can take your pick, folks. Happy nerding it out.