TE Connectivity's UAM Wi-Fi Triple Band Antennas offer a compact alternative for terminal antennas

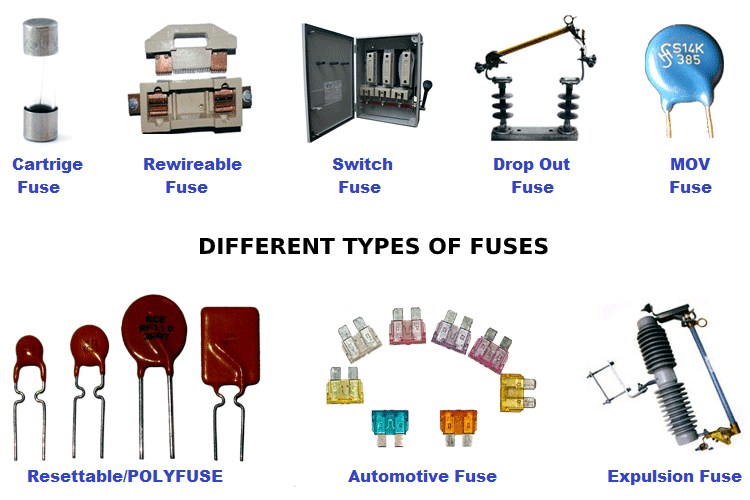

Different Types of Fuses and their Applications

A fuse is probably the simplest electrical device, but its function is critical in protecting electrical circuits from damage. Fuses are found in every circuit in one form or another in various shapes, sizes, and ratings. In this article, we will learn how a fuse works and about the different types of the fuse.

What is a Fuse and How does a fuse work?

The primary job of a fuse is to break the circuit if a current higher than desired is drawn by the circuit, thus preventing damage due to short circuits.

The simplest kind of fuse consists of a resistive element, selected carefully for its melting point. The working principle of a fuse is as follows, when a current passes through this element, a small voltage drop (small enough so the circuit downstream won’t be affected) is created across the element, and some power is dissipated as heat. The temperature of the element thus increases. For normal currents, this temperature increase is not enough to melt the filament. However, if the current draw exceeds the rated current of the fuse, the melting point is quickly reached. The resistive element melts and the circuit is interrupted. The thickness and length of the resistive element determine the rated current.

Fuse elements are made of zinc, copper, silver, aluminium or other alloys to provide predictable trip currents. The element must not oxidize or corrode over time.

Symbol of a Fuse

The standard IEEE/ANSI symbols for the fuse is as follows:

However, the IEC fuse is slightly different:

Types if Fuse

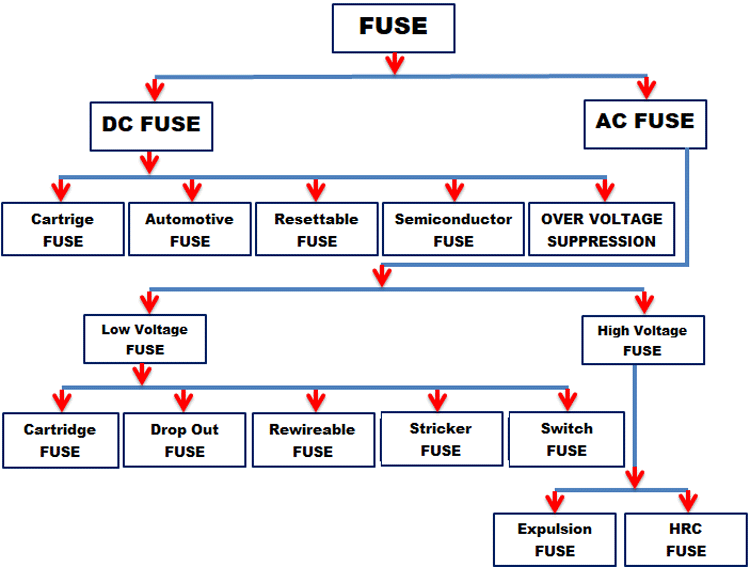

Fuses can be divided into two major categories, AC fuses, and DC fuses. The below block diagram illustrates the different types of the fuse under each category. We will discuss each fuse in brief in our article.

What is AC fuse and DC fuse?

As the name itself suggests, AC fuses are the ones we use in an AC circuit and the DC fuses are the ones we use in a DC circuit. The AC fuses are commonly rated for 120V or 240V depending on the grid voltage it is used with. they are designed to handle the alternating nature of the AC voltages. Like AC fuses, DC fuses are rated for particular voltage levels, but because DC voltage might be less forgiving than AC voltage, they must be more voltage-specific.

DC Fuses

1. CARTRIGE FUSES

This is the most common type of fuse. They are also called glass fuse because the fuse element is encased in a glass envelope that is terminated by metal caps. The fuse element is encased in a glass envelope that is terminated by metal caps. The fuse is placed in an appropriate holder. Since the glass envelope is clear, it is easy to visually determine if the fuse is blown.

There are many variants of this design, including slow blow fuse and fast blow fuse. Slow blow fuses have a larger element that can handle overcurrent for a relatively short period of time and are unaffected by spikes in the appliance. Fast blow fuses react instantly to current spikes.

Some variants of this fuse are encased in ceramic to withstand high temperatures. Fuses for high voltage applications are filled with sand or oil. This is to prevent arcing between the two ends of the fuse after it has blown. SMD variants of cartridge fuses also exist for direct PCB mounting.

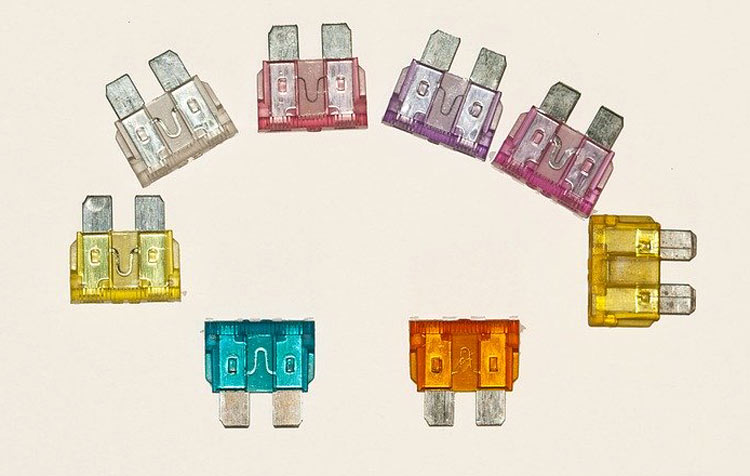

2. AUTOMOTIVE FUSES

These fuses are specifically designed for automotive systems that run up to 32V and occasionally 42V. They are also called blade fuse because they come in ‘blade’ form (a transparent plastic envelope with flat contacts) and are colour-coded according to rated current. Some of these types are also used in other high-power circuits. The most common automotive refuse types are micro2, micro3, LP-min(APS), mini (ATM/APM), regular(APR / ATC / ATO / ATS) and maxi(APX). This classification is based on the physical dimensions of the fuse.

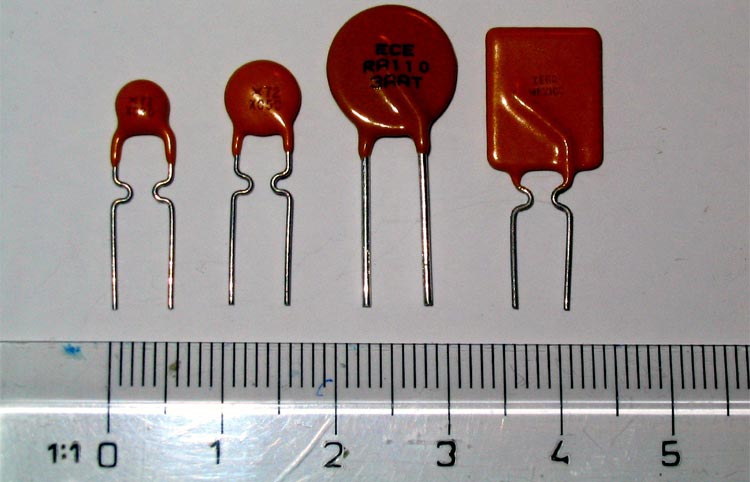

3. RESETTABLE FUSES/POLYFUSE

Like their name suggests, these fuses are self-resetting. They contain carbon black particles embedded in organic polymers. Normally, the carbon black makes the mixture conductive. When a large current flows, heat is generated which expands the organic polymer. The carbon black particles are forced apart, and conductivity decreases to the point where no current flows. Conductivity is restored as temperature decreases. Thus, the fuse does not have to be physically replaced. This kind of fuse is also called a PTC, meaning positive temperature coefficient, since resistance increases with temperature.

PTC Fuse is ubiquitous in computer power supplies and phone chargers. They are particularly handy here since replacement is difficult. For the same reason, they are used in aerospace devices.

PTCs are easily identified by their yellow-orange colour and disc (and occasionally rectangular) shape in their through-hole variants. SMD poly fuses usually come in green with white markings or black with gold markings. PTCs are available in virtually every current rating.

4. SEMICONDUCTOR FUSES

The power dissipated by a semiconductor increases exponentially with current flow, and hence semiconductors are used for ultrafast fuses. These fuses are usually used to protect semiconductor switching devices that are sensitive to even small current spikes.

5. OVERVOLTAGE SUPPRESSION

Sometimes voltage spikes can be harmful to circuits too, and often an overvoltage protection device is used with a fuse to protect against both voltage and current spikes.

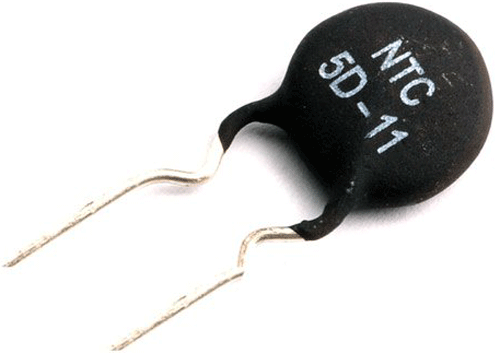

NTCs (negative temperature coefficient) are placed in parallel with the supply. When the supply voltage spikes, NTC Fuses decrease resistance due to higher current flow and ‘absorb’ spikes.

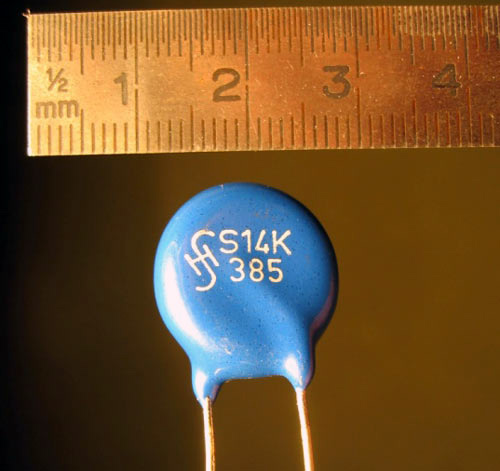

Metal oxide varistors (MOVs) are semiconductor like devices that bidirectionally absorb voltage spikes. You can learn more about MOV and its working using the linked article.

AC FUSES

HIGH VOLTAGE FUSES:

These fuses are used in high voltage AC transmission lines where voltages can exceed several hundreds of kilovolts. Some of the most popular high-voltage AC fuses are AJT125, ATQR4, TRS150R and AJT50.

HRC (High Rupture Current) fuses: HRC fuses are cartridge type fuses consisting of a transparent envelope made of steatite (magnesium silicate). The fuse is filled with quartz powder (and in the case of a liquid-filled HRC fuses, a non-conducting liquid like mineral oil) that acts as an arc extinguishing agent.

These fuses are used for very high fault currents.

Expulsion Fuses: These fuses are filled with chemicals like boric acid that produce gases on heating. These gases extinguish the arc and are expelled from the ends of the fuse. The fuse element is made of copper, tin or silver.

LOW VOLTAGE FUSES:

These fuses are used in the relatively low voltage distribution networks.

Cartridge fuses: They are very similar to cartridge DC fuses. They consist of a transparent envelope surrounding the fuse element. They can be plugged in (blade type) or screwed into a fixture (bolt type).

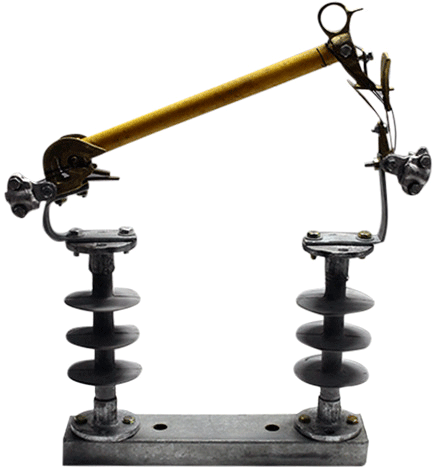

Drop out fuses: They contain a spring-loaded lever arm that retracts when a fault occurs and must be rewired and put back in place to resume normal operation. They are a type of expulsion fuse.

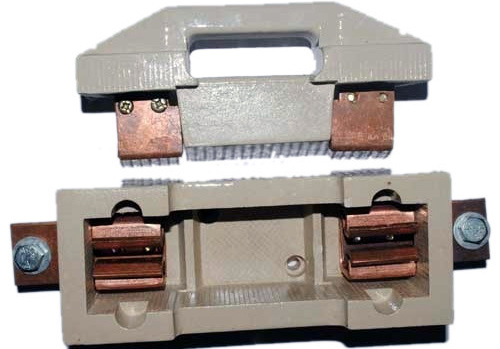

Rewireable fuses: They are a simple reusable fuse used in homes and offices. They consist of a carrier and a socket. When the fuse is blown, the carrier is taken out, rewired and put back in the socket to resume normal operation. They are somewhat less reliable than HRC fuses.

Striker fuse: These fuses are provided with a spring-loaded striker that can act as a visual indicator that the fuse has blown and also activate other switchgear.

Switch fuse: A handle that is manually operated can connect or disconnect high current fuses.