Optimized at frequencies beyond traditional industry targets to support emerging applications

Crystal Oscillator vs MEMS Oscillators

Crystal Oscillators and MEMS Oscillators are two of the most commonly used clock generators. Choosing one over the other depends on various parameters such as stability, cost, power consumption, and how they align with the application requirements.

In this article, we’ll compare MEMS vs Crystal oscillators to help you decide which one best suits your requirements. But before diving into the differences between the two, let's understand the basics of these oscillators.

What is a Crystal Oscillator?

Crystal oscillators use quartz crystal to generate stable and precise timing signals. In crystal oscillators, the frequency is determined by the size and shape of a crystal. This is achieved by precisely cutting, shaping, and sizing a thin piece of quartz crystal. They are known for their exceptional quality factor (Q), meaning they lose energy more slowly and can maintain precise frequency stability over long durations. Due to their high ‘Q,’ they provide low phase noise and jitter.

There are different types of crystal oscillators available such as Standard crystal oscillators (XO), Temperature-Compensated Crystal Oscillator (TCXO), Voltage Controlled Crystal Oscillator (VCXO) and Oven-Controlled Crystal Oscillator (OCXO). Each comes with different features and is designed for specialized applications. New-generation crystal oscillators come with advanced features like built-in temperature compensation circuit, programmable frequency setting, and low power consumption.

They are used in a wide range of applications, i.e. communication systems, measuring instruments, computers, digital systems, medical equipment, automotive electronics, etc.

How does Crystal Oscillator work?

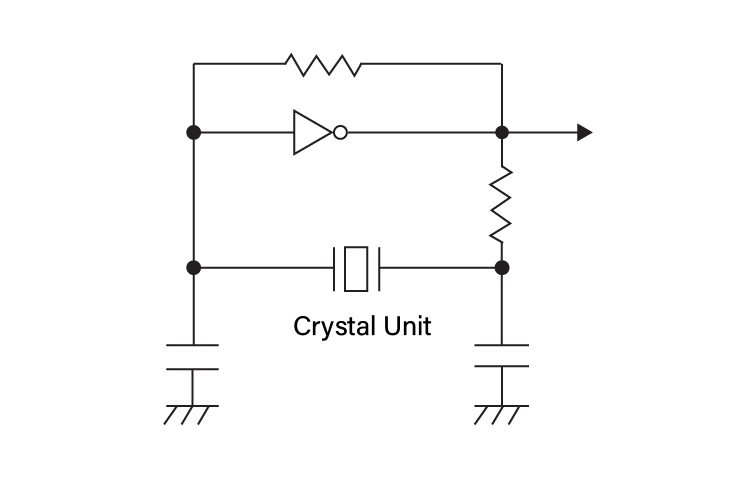

The following figure shows the block diagram of the crystal oscillator.

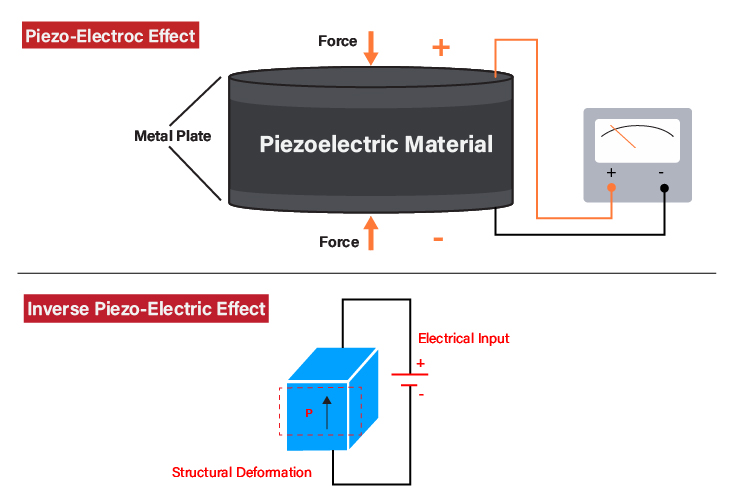

In the circuit, a quartz crystal resonator is used as the frequency-determining element along with a comparator, resistors and capacitors. The oscillator works on the principle of inverse piezo-electric effect. Piezo-electric effect is an electromechanical phenomenon that causes a potential difference across the opposite ends of the crystal whenever mechanical pressure is applied to it. Therefore, an AC voltage is generated across the crystal.

The inverse process is utilized in crystal oscillators. When an AC voltage is applied to the crystal, the crystal changes its shape and begins to vibrate or oscillate. These oscillations occur at the crystal's natural resonant frequency, which is determined by its shape and size.

The higher Q value allows the quartz crystal to sustain oscillations longer however they cannot resonate indefinitely due to energy losses from mechanical vibrations. Therefore, to maintain continuous oscillations, an amplifier is needed. The amplifier amplifies the oscillations and feeds them back to the crystal. This way a continuous clock signal is generated.

Crystal Oscillators Manufacturers

The manufacturers of crystal oscillators are Epson Toyocom, TXC Corporation, Wenzel Associates, Vectron International, Euroquartz, Murata Manufacturing Co. Ltd, NDK, Bliley Technologies, CTS Corporation, Citizen Watch Co. Ltd., NEL Frequency Controls Inc., Greenray industries, Abracon etc.

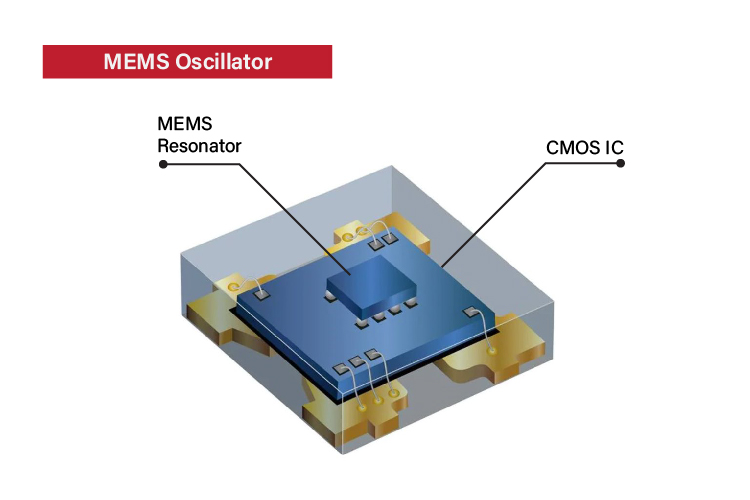

What is a MEMS Oscillator?

MEMS, or microelectromechanical system oscillators, are based on new-generation MEMS technology. These oscillators are manufactured using Silicon Wafer Processing technique, making them small in size and cost-efficient. The most common types of MEMS oscillators include Temperature Compensated Oscillator (TCXO), Spread Spectrum Oscillator (SSXO), Voltage Control Oscillator (VCXO), and Digitally Controlled Oscillator (DCXO).

The biggest advantages of these modern timing devices are their flexibility and programmable timing features that improve system performance. Their programmable architecture allows them to be programmed for any output frequency, output format, and supply voltage within a wide range, so they are readily available in any frequency. Additionally, they include configurable output drivers with adjustable drive strength for impedance matching and emissions reduction.

With recent advancements in technology, modern MEMS oscillators offer good performance and reliability, sometimes better than crystal oscillators. They include features like immunity to noise coupling, low jitter, reliable startup in harsh conditions, and resistance to vibration, making them ideal for power-sensitive and space-constrained applications. Some MEMS devices provide differential outputs that minimize noise and improve performance in high-speed data transfer and timing-critical operations.

How does MEMS Oscillator work?

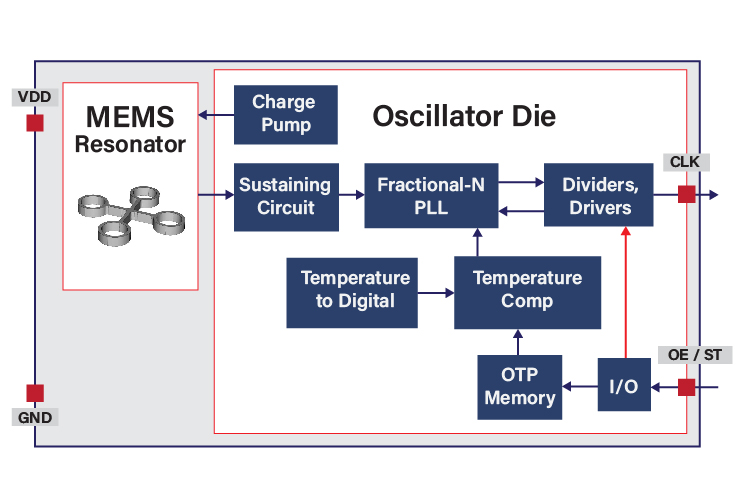

The following figure shows the block diagram of the typical MEMS oscillator.

Note that different oscillators have individual architectures targeting different applications. As shown in the above figure, MEMS oscillator combines a micro-electromechanical systems resonator with a programmable oscillator IC to generate precise timing signals. The resonator is made of single-crystal silicon, which vibrates at a specific frequency when electrically excited.

When voltage is applied, the vibrations are induced in the resonator. The signal generated by the resonator is weak and requires amplification. The sustaining circuit amplifies this signal, which is then processed through a Fractional-N phase-locked loop (PLL) block that multiplies the resonator's base frequency to achieve the desired output.

MEMS oscillators also include temperature-to-digital converter and temperature compensation circuit to maintain frequency stability across a wide operating temperature range. Then, the signal undergoes further refinement through dividers and drivers to produce a clean and stable clock (CLK) output.

The One-Time Programmable (OTP) memory stores the oscillator's configuration settings, such as frequency values and temperature compensation parameters. An input/output (I/O) interface allows users to control features like enabling or disabling the output.

The MEMS oscillator typically contains 4 pins:

-

VDD: The typical value of VDD (supply voltage) applied to MEMS oscillators usually ranges between 1.8V to 3.3V DC, depending on the specific MEMS device and its application.

-

GND: This is the Ground pin.

-

CLK: This pin is the clock output of the MEMS oscillator.

-

OE/ST: It is an output Enable/Standby pin. It is an active HIGH input to the MEMS oscillator. When OE is enabled (logic HIGH), the CLK output is active and provides the clock signal. When OE is disabled (logic LOW), the CLK output is turned off or goes into a high-impedance state (Hi-Z), depending on the configuration.

MEMS Oscillators Manufacturers

The manufacturers of MEMS oscillators include SiTime Corporation, Microchip technology, Abracon, IQD Frequency products, Daishinku DAISHINKU CORP, Vectron International, Rakon, TXC Corporation, etc.

Comparing Crystal Oscillator to MEMS Oscillator

Now that we’ve learned the basics of the two, let’s compare them based on some important parameters:

Power Consumption

Crystal oscillators consume less power due to their simple circuit structure and fundamental harmonic oscillation. Traditional MEMS oscillators consume higher power due to complex structure and increased circuitry. However, the latest power-optimized MEMS devices consume less power compared to traditional crystal oscillators. They can even be used for battery-operated devices, wearable technology, and IoT devices.

Oscillator Start-Up

An oscillator with a fast startup ensures shorter wakeup cycles, which contributes to longer battery life. This feature is particularly valuable for consumer electronics and home automation applications, where systems frequently turn on and off to conserve energy. Crystal oscillators achieve stable operation almost immediately after applying power. In contrast, MEMS oscillators take longer to stabilize. However with modern MEMS devices this is no longer an issue, they come with fast start-up time.

Jitter and Phase Noise

Jitter and phase noise are key factors to measure oscillator performance. Jitter is the timing variation of a clock signal, while phase noise measures phase changes in the frequency domain. They are critical parameters that directly impact the frequency stability of a signal.

Crystal oscillators offer lower phase noise and jitter as they have high “Q” or Quality factor. Earlier MEMS Oscillators had higher phase noise because the silicon resonator has poor “Q” and complex structure. However, the latest MEMS oscillators have shown significant improvement in phase-noise and jitter specifications. Some even provide ultra-low jitter performance used in demanding applications including 5G network infrastructure, data centers, optical modules, and Internet of Things (IoT) devices.

Frequency Stability

Frequency stability is the most important feature of an oscillator. It is the ability to provide a constant frequency output under varying load conditions. It is typically expressed in parts per million (ppm) or parts per billion (ppb).

Crystal oscillators maintain exceptional frequency stability, showing minimal deviation over time, while some MEMS oscillators exhibit noticeable frequency jumps due to PLL adjustments. However MEMS oscillators that include temperature compensation circuitry deliver outstanding frequency stability over temperature. Their excellent frequency stability and low jitter are particularly useful in applications requiring consistent performance and minimal signal distortion.

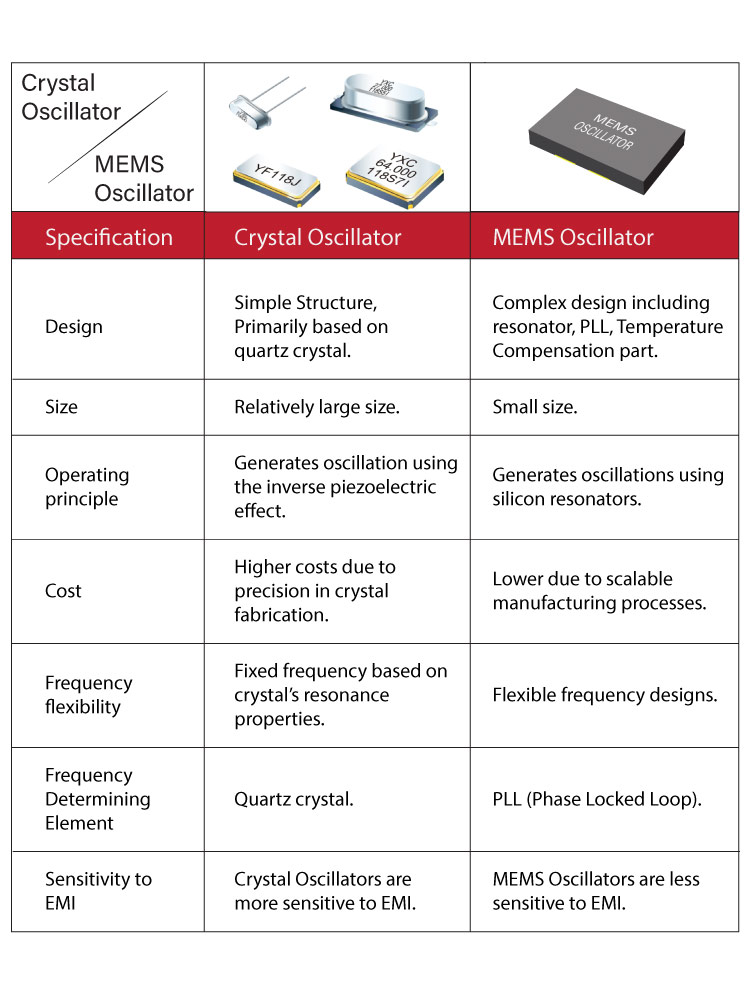

Differences between MEMS Oscillator and Crystal Oscillator

The following table summarizes the difference between MEMS Oscillator and crystal oscillator.

Crystal oscillators are simple structures based on quartz crystals, but MEMS oscillators have a complex design involving resonators, PLLs, and temperature compensation. Also, Crystal oscillators are relatively larger in size compared to compact MEMS oscillators, and their operating principle relies on the inverse piezoelectric effect, whereas MEMS oscillators use silicon resonators.

When comparing cost, Crystal oscillators are more expensive due to precise crystal fabrication, while MEMS oscillators are cost effective because of its easily scalable manufacturing processes. Crystal oscillators offer a fixed frequency based on crystal resonance, whereas MEMS oscillators provide flexible frequency designs. The frequency-determining element for crystal oscillators is the quartz crystal, while MEMS oscillators use a phase-locked loop (PLL). Lastly, crystal oscillators are more sensitive to EMI, whereas MEMS oscillators are less affected.

Both MEMS and Crystal oscillators have advantages and applications. The choice between the two depends on the specific requirements of the application, such as precision, size, stability, power consumption, and cost. While traditionally crystal oscillators are used widely in many applications, MEMS-based oscillators are becoming increasingly popular due to their performance, short lead times, small form factor, and programmable timing features. Today, MEMS oscillators are steadily replacing crystal oscillators in electronic devices. If you are still looking for alternate options you can also check out Crystal Oscillator Vs Resonator article to know how crystal socailltors compare with Resonatros.