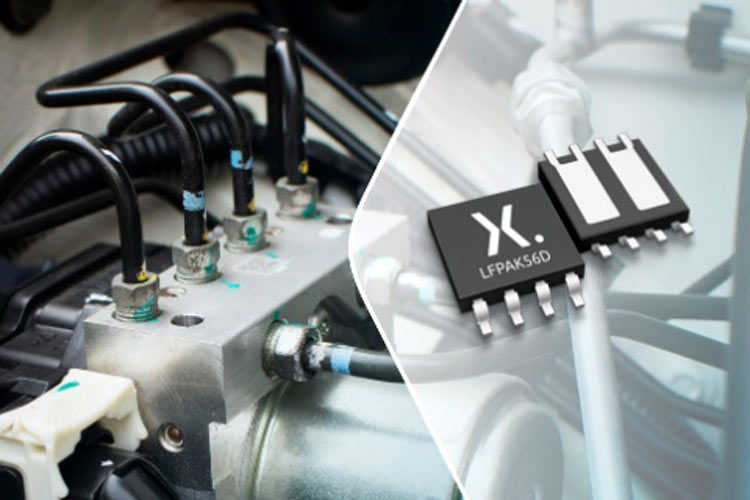

LEFPAK56D - Repetitive Avalanche Application-Specific FET to Save Space, Reduce Component Count and Improve Reliability in Powertrain Applications

Nexperia has introduced the Repetitive Avalanche Application-Specific FET (ASFET) portfolio that can be used to control automotive inductive loads such as solenoids and actuators. The AEC-Q101- qualified LEFPAK56D has been tested to one billion avalanche cycles and provides a faster turn-off time (up to 4X). When compared to boost topology, the Automotive Repetitive Avalanche ASFET family of products simplify designs by providing up to 30% components footprint efficiency due to a possible reduction of up to 15 board components.

With an input voltage of 40 V and 60 V with typical RDS(ON) ratings from 12.5mΩ to 55mΩ, the devices are packed in the LEFPAK56D (Dual Power-SO8) copper-clip package technology. The highly robust package features gull-wing leads for increased board level reliability and improved manufacturability including automated optical inspection (AOI).

Features of LEFPAK56D ASFET

- Qualified to AEC-Q101

- Guaranteed repetitive avalanche performance, tested up to 1 billion cycles

- Rugged silicon technology combined with the thermal performance of LFPAK ensures die temperature stays below 175 °C

- The simplicity of using a single MOSFET reduces BOM and circuit complexity, delivering system cost and space savings

- Modern trench alternative to older planar technologies

- Offers increased efficiency and faster switching in comparison to the freewheeling diode approach

Note: More technical information can be found in the BUK9K35-60RA Datasheet linked at the bottom of this page and on the LEFPAK56D ASFETs product page.