Coreless DC Drone Motor

Coreless motors are a type of DC motors that are specially used for battery-powered applications because they draw extremely low currents in no-load conditions and are mainly used in small-scale aircraft, and medical applications. The motors are extremely small and in terms of power handling capacity, they can handle 5W of power and run at a speed of 50000rpm on 3.7V. Its only 2.5g weight that can effectively reduce the weight of the aircraft.

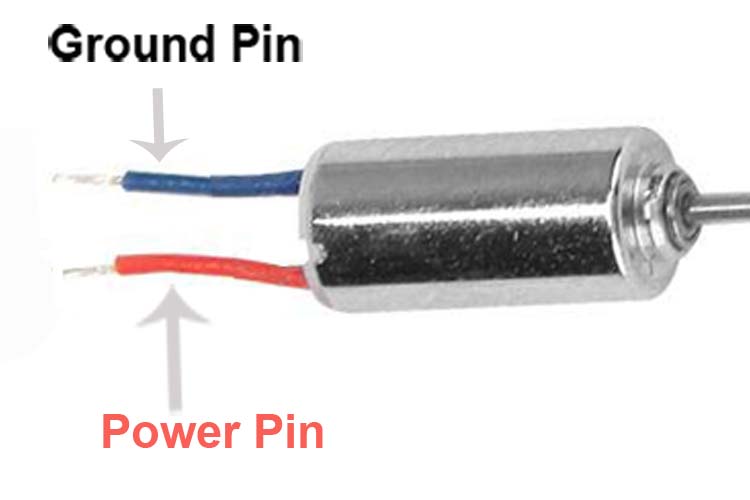

Coreless Drone Motor Pinout Configuration

|

Pin Number |

Pin Name |

Description |

|

1 |

VCC |

+ Voltage source or Power Pin |

|

2 |

GND |

- Voltage source or Ground Pin |

Features and Specifications

- Diameter: 7 mm

- Length: 16.5 mm

- Shaft length: 6.3 mm

- Shaft diameter: 0.8 mm

- Weight: 2.5 g

- Speed: 50000 rpm

- Rated voltage: 3.7 V

- Rated current: 100mA

- Max Current: 1.4A

- Wire length: 50 mm

What is a Coreless DC Drone Motor?

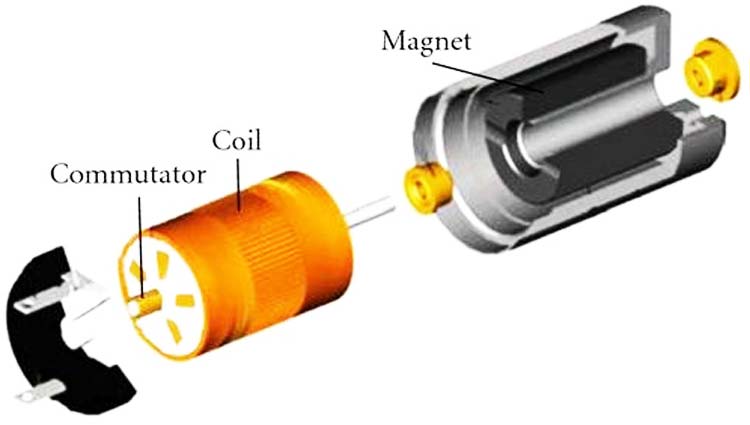

When we are talking about a DC motor, it has a laminated core inside in which the copper wire is wounded, but in a coreless DC motor there is no laminated core, instead, the rotor is wounded in a honey comb fashion to form a cylinder, and this cylinder is often held by thin epoxy resin. The stator is made out of a rare earth neodymium magnet and is located inside the core of the motor.

In a conventional DC motor, the bushing is a key part that is made out of rubber which reduces vibration but in a coreless DC motor, this bushing is made out of silver, gold, platinum, or palladium, that is paired with a metal commutator. This design enhances efficiency thus is used in the ultra-low-power application. When this type of design is used in high to moderate power applications copper is used, the copper-graphite combination is more suitable for high power applications. A coreless DC motor provides several advantages over traditional DC motors. It recurs less iron to build the motor so its efficiency increases rapidly because of which this motor can accelerate and decelerate rapidly, and less iron means less that adds into the efficiency which is why reaching 90% efficiency is possible. The coreless design reduces winding inductance, as a result, sparking in between the commutator and bushes reduces rapidly that reduces EMI interference.

Applications

- Small Drones

- High power small submersible pumps

- Laboratory equipment

2D Model and Dimensions

If you are designing a PCB or Perf board with this component then the following picture will be useful to know its package type and dimensions.