TE Connectivity's UAM Wi-Fi Triple Band Antennas offer a compact alternative for terminal antennas

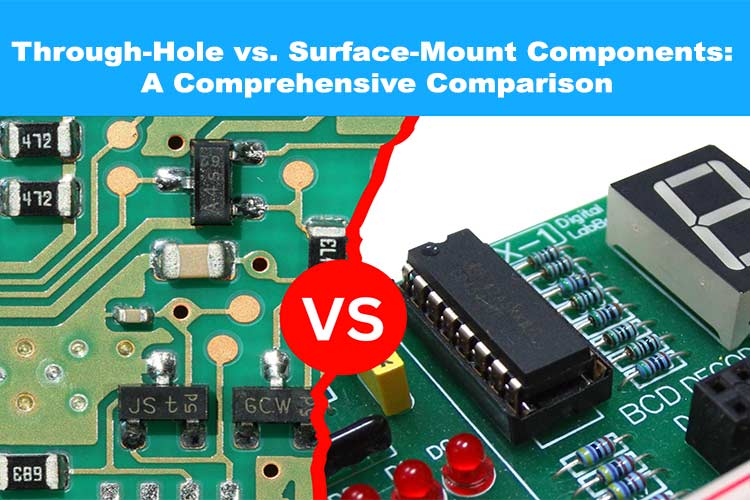

Through-Hole vs Surface Mount Components: A Comprehensive Comparison

In the world of electronics manufacturing, the debate between through-hole (THT) and surface-mount (SMD) components has been ongoing for years. Each type has its unique advantages and disadvantages, and the choice between them depends on several factors, including the application, production volume, design complexity, and budget. In this article, we will explore the pros and cons of both through-hole and surface-mount components, as well as dive into cost comparisons, design considerations, and assembly considerations to help you make an informed decision.

SMD vs THT - An Overview

Surface-mount technology (SMD) and through-hole technology (THT) are two primary methods for mounting electronic components onto printed circuit boards (PCBs). SMD components are soldered directly onto the PCB's surface, while THT components pass through holes in the PCB and are soldered on the opposite side.

Pros and Cons of Surface-Mount Components (SMD)

- Space Efficiency: SMD components are significantly smaller than their through-hole counterparts, allowing for higher component density on PCBs. This results in more compact and lightweight electronic devices, ideal for space-constrained applications.

- High-Frequency Performance: SMD components exhibit lower parasitic capacitance and inductance due to shorter lead lengths, enabling better high-frequency characteristics and reduced signal distortion.

- Automated Assembly: SMD components are well-suited for automated assembly processes, leading to faster production cycles and reduced labour costs. Pick-and-place machines can accurately position SMD components, enhancing manufacturing efficiency.

- Cost-Effectiveness for Mass Production: While SMD components might be costlier initially, their benefits in mass production outweigh the initial investment due to faster assembly and reduced labour expenses.

- Thermal Performance: SMD components' direct contact with the PCB enhances heat dissipation, reducing the risk of overheating and improving overall thermal performance.

However, it is essential to consider some of the disadvantages associated with SMD components:

- Fragility: SMD components are more delicate than THT components, making them susceptible to damage during handling or rework processes.

- Challenging Hand Soldering and Repairs: Miniaturization makes hand soldering and repairs difficult for SMD components, necessitating specialized equipment and skilled technicians.

- Sensitivity to Environmental Factors: SMD components are more vulnerable to environmental stresses, such as moisture and vibration, due to their surface-mounting nature.

- Thermal Issues: Even though we have stated that SMD components offers better thermal performance, careful thermal design consideration is needed to ensure it. Otherwise, it can have adverse effects.

Pros and Cons of Through-Hole Components (THT)

- Mechanical Stability: Through-hole components offer stronger mechanical bonds with the PCB, making them more resistant to mechanical stress and suitable for applications subjected to frequent physical shocks.

- Ease of Manual Assembly and Repairs: THT components are easier to handle, making manual assembly and repairs feasible without the need for advanced equipment or techniques.

- Suitable for Prototyping: Through-hole components are often preferred in prototyping and DIY projects, where flexibility and ease of experimentation are crucial.

- Better Tolerance to Harsh Environments: THT components generally exhibit higher reliability in harsh operating conditions, making them suitable for rugged applications and industries like aerospace and automotive.

However, through-hole technology has some drawbacks:

- Larger Footprint: THT components take up more space on PCBs due to their larger size and lead spacing, limiting PCB density and potentially increasing production costs.

- Slower Assembly Process: Hand soldering through-hole components is time-consuming, leading to longer production cycles and higher labour costs for large-scale manufacturing.

- Signal Disturbance: The leads of THT components can act as antennas, leading to potential signal interference and degradation in high-frequency circuits.

Cost Comparison

In terms of component cost, surface-mount components tend to be more expensive than through-hole components. This cost difference is primarily due to the additional manufacturing processes involved in producing smaller, more sophisticated SMD components. However, as mentioned earlier, SMD components offer cost advantages in high-volume production due to faster assembly times and lower labour expenses.

Design Considerations

When choosing between SMD and THT components for a specific project, several design considerations come into play:

- Board Real Estate: If space is limited and miniaturization is a priority, SMD components are the better choice due to their compact size and high component density capabilities.

- Assembly Method: If you have access to automated assembly equipment and plan to produce in large quantities, SMD components are more suitable. However, for smaller production runs or prototyping, through-hole components offer more flexibility and ease of manual assembly.

- Environmental Factors: Consider the operating environment of the end product. Harsh conditions may favour through-hole components for their mechanical stability and higher reliability.

- Thermal Stability and performance: While designing it is important to consider the thermal performance. It will depend on the cooling solutions we opt for. So it is important to choose the components accordingly.

Assembly Considerations

The assembly process can heavily influence the choice between SMD and THT components:

- Automated vs. Manual Assembly: SMD components are better suited for automated assembly lines, while THT components are more compatible with manual soldering and repairs.

- Soldering Techniques: SMD components require reflow soldering, whereas through-hole components are compatible with wave soldering or manual soldering.

Conclusion

In conclusion, the choice between through-hole and surface-mount components depends on various factors such as space constraints, production volume, design complexity, and operating environment. SMD components offer advantages in terms of space efficiency, high-frequency performance, and cost-effectiveness for mass production. On the other hand, THT components excel in mechanical stability, ease of manual assembly, and suitability for prototyping. Designers and manufacturers must carefully assess their specific project requirements and select the appropriate components based on the application's needs and the available resources for assembly. Whether it's embracing miniaturization with SMD components or relying on the mechanical robustness of through-hole technology, making an informed decision will ultimately lead to successful electronic designs and applications.